Achieve the

PERFECT WELD

Specialty Welding & Metal Fabrication Since 1978

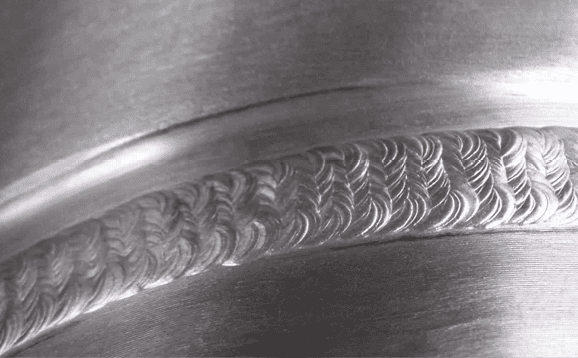

Quality Workmanship is Our Product

Nadcap Accredited Fusion Welding

The Perfect Weld for Critical Applications

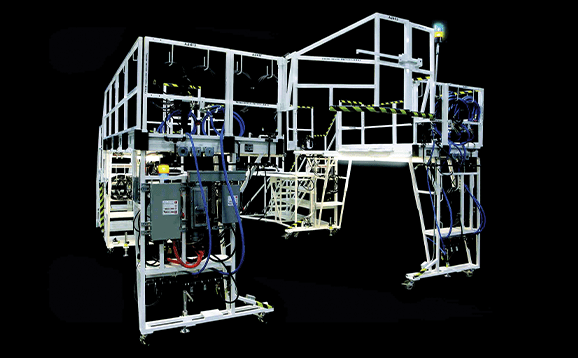

OUR INVESTMENTS IN TECHNOLOGY, PEOPLE & EXPERIENCE PRODUCE THE PERFECT WELD

JOIN US IN

OUR QUEST

TO PARTNER

WITH YOU

By implementing continuous improvement and working together as a team, Advance Welding strives to exceed customers’ requirements and expectations. It is this work ethic that keeps Advance Welding a leader in the welding and metal fabrication industry.

Certified

Welding

Accredited with merit to the requirements of Nadcap for Welding and serving the aviation industry as an FAA approved repair station. More Info.

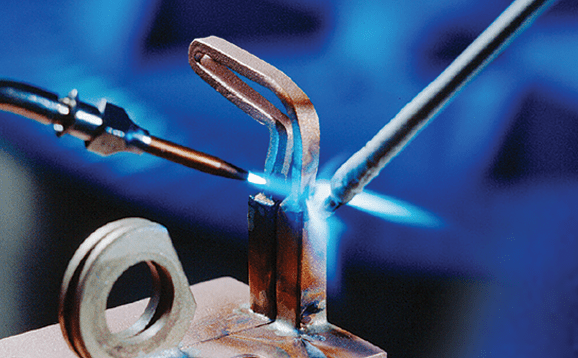

Certified

Brazing

Precision

Manufacturing

THE VERSATILITY TO SERVE MANY LEADING INDUSTRIES

WHAT SOME OF OUR LOYAL CUSTOMERS ARE SAYING

Advance Welding is truly a part of our team. They are always ready with the best customer service and technical support. They are always working to exceed our expectations. Best in class

Just a quick note to express our sincere gratitude for the outstanding welding job you did for us. Our customer was unable to tell where the repair was done on the insert that you welded in five areas. Without your expertise, this would have been impossible.

Best wishes to you and the family for continued success.

Many Thanks To The Staff At Advance Welding.

Several years ago we decided to end our inhouse brazing and soldering operations for several reasons, the most important being that it wasn’t an area of expertise for us. It wasn’t long after asking some of our local accounts who they might recommend before we hooked up with Advance Welding, it was the best decision we could have made.

It wasn’t long before Chris Kielb the owner sat with us at their facility and explained their operation and capabilities to me, I knew I was in the right place.

I appreciate the quick service we receive from their team on the items our customers are pushing us for, the quality of work we receive, the warm reception we receive from Sue at the front desk who always greets us with a smile. And then there’s Kevin who always insists that our tools be accompanied with a drawing ( it’s for our own good, he wants to make sure our customers are getting what they pay for).

Our only regret is that we didn’t start this program a long time ago, we’re looking forward to another prosperous year with Advance Welding as our business continues to grow.

CERTIFICATIONS

ITAR Registered